Smart Construction Machines. The digital construction industry in 2025.

Smart Construction Machines. The digital construction industry in 2025.

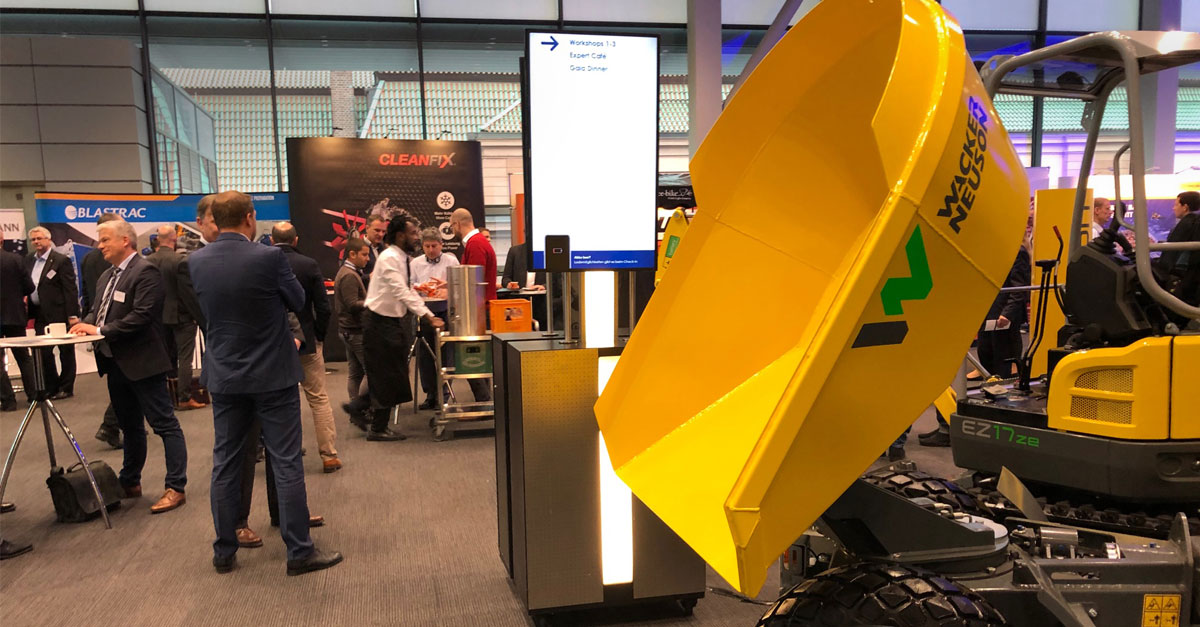

This was the motto of the 2nd Construction Equipment Forum, which took place this time in Mannheim. Professor Dr. Johannes Walter, host and head of IPM, opened the event. With approx. 400 participants, 73 partners and sponsors as well as approx. 60 exhibitors, the Construction Equipment Forum has grown considerably compared to the inaugural event one year ago in Hanover. In addition to the IPM Institute as organizer, the companies Wacker Neuson, Ammann, Bosch and STRABAG are founding partners and sponsors of the event.

Smart Construction. New drives. Automation – What these catchwords mean

Prof. Walther highlighted three areas of innovation supported by the Construction Equipment Forum:

- Smart Construction for the connected construction site (live data, construction machines communicating with each other and artificial intelligence)

- New drives (electric drive, but also new fuels – especially with regard to the challenge of further reducing carbon emissions)

- Automation (new application scenarios for semi/fully automated machines and robots)

Transformation in the construction industry towards digitization and climate protection

Time has changed – as the two opening lectures showed:

Margit Dietz, spokeswoman for the building contractors in the Central Association of the German Construction Industry, made it clear that BIM (Building Information Modeling) is not a universal remedy. After all, digitization is not an end in itself. She called for 5G, open-technology competition between the various types of drive, and cooperation between highly qualified engineers and IT experts. Furthermore, she advocated product-neutral solutions and open data interfaces.

The second opening lecture was a big bang, which caused many subsequent discussions: Clara Mayer, an 18-year-old environmental activist and “future expert” of “Fridays for Future”. She called on the participants, being experts in the construction industry, to take extensive measures to mitigate their impact on the global climate. She made it clear that her participation should not be misunderstood as moral absolution in the sense of greater environmental awareness. Rather, she held the construction industry accountable for more environmental protection without going into further details. It is also positive that she was available for discussions after her demanding lecture.

A vision for the digital construction site of the future

Karsten Elles of Komatsu presented how the company sees the manufacture of construction machinery as part of a bigger picture, including upstream and downstream processes. The goal of everything: increased customer benefit. A captivating video showed how an intelligent construction site of the future could look like: autonomous construction machines that are controlled and monitored remotely in an operation center.

Topics discussed

Another highlight was certainly the morning panel discussion on “Smart Construction: From mechanized to digital construction”. Participants included PwC (Jörg Asma), Ammann (Dr. Anton Demarrels) and Q Point (Marcel Pilger), moderated by Professor Dr. Matthias Tomenendal of HWR Berlin.

It became clear that for successful digitization the fundamentals must first be in place with the partners involved (“first fix the basics”); and the importance of open interfaces with the highest possible standardization. PwC stressed the topic of cyber security. The audience was also able to participate directly in the discussion with interactive questions.

The panel discussion in the early afternoon was highly commendable. Topic: The electric construction machine and its application possibilities. It also dealt with questions of profitability and sustainability. Prof. Dr. Alexander Tsipoulanidis (HWR Berlin) interviewed the construction machinery manufacturer Liebherr (Rudolf Ellensohn) and the battery manufacturer Akasal (Felix von Borck). In the open discussion, topics such as compliance with minimum social standards in cobalt mining or the “second life” of a battery or battery return and recycling were also addressed.

The conference program was rounded off by workshops on smart construction, new drives or automation, a panel of experts on retrofitting and a further panel discussion.

High interest in the exhibition

Not only during the breaks there was a lively exchange at the approx. 60 booths. Here, trend topics such as “construction site measurement by drones” and increasing the efficiency on the construction site through more integration and integrated resource planning were discussed. There was also great interest in the SupplyOn booth, which was even part of the exhibition tour.

The Construction Equipment Forum demonstrated this: The future of the construction industry is becoming increasingly digital, more eco-conscious and connected. Let us help to shape this.