Volatility hinders logistics planning – more responsibility for forwarding companies?

![]()

In its survey entitled “Market volatility in transport and logistics”, the BME predictably noted at the end of 2013 that it is more and more difficult for forwarding and shipping companies to plan their warehouse and fleet capacities owing to the growing volatility resulting from increasing globalization.

In my opinion, the most important findings of the survey were as follows:

- Quantity fluctuations are leading to ever higher transport costs.

- Two thirds of the companies surveyed expect this volatility to increase further, especially on an international level.

- 94 percent of service providers regard closer cooperation with customers and suppliers as a key measure when it comes to improving their own business forecasts and planning.

- Intensive market research and a presence in the various regions can help to “gain a better idea of the various developments in specific regions.”

- Although bundling and a more efficient use of existing networks cannot reduce fluctuations, they can reduce costs considerably.

- Shipping companies clearly expect quantities to increase more than forwarding companies.

- While the majority of shipping companies expect price increases for the transport of loads and individual items, far fewer forwarding companies expect this to be the case.

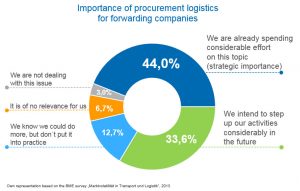

- 44 percent of companies are already focusing on the issue of procurement logistics. A further third of forwarding companies say that they intend to step up their activities

- considerably in the future. Only just under seven percent said that procurement logistics is of no relevance.

- Only nine percent of the companies surveyed said that they were following an approach whereby they organize incoming shipments themselves.

- More than 50 percent of the firms said that they restrict their procurement logistics activities to individual selected suppliers.

- If geographical considerations play a role, firms’ willingness to assume responsibility for procurement logistics themselves decreases the further they are from suppliers. This could be due to the increasing complexity of transport processes which demand a great deal of specialist, national know-how on the part of the firms.

- 14 percent of the firms said that they had absolutely no involvement in procurement logistics. According to these firms, they receive everything “delivered to their doors“.

Procurement logistics gaining in importance

These results clearly show that procurement logistics is becoming increasingly important, especially from a costs point of view. In light of the future price increases, shipping companies have a more negative view than forwarding companies. This could be down to the fact that they regard coping with the increasing complexity as one of their main tasks. As revealed by the survey, numerous forwarding companies are cautious about taking on more responsibility. If this trend proves to be true, the shipping companies as transport and stock management providers will need to master these more complex tasks instead of the forwarding companies. This is hardly likely to result in price reductions.

More responsibility for forwarding companies?

If the forwarding companies want to achieve cost stability or even cost reductions, this will probably not be possible without them taking on more responsibility for procurement logistics. Global companies such as a number of our customers regard this as a major opportunity to significantly reduce current transport cost volumes. Essentially speaking, this will be achieved by intelligent route planning with corresponding bundling of shipments, greater use of HGV capacity and the awarding of transport jobs to the cheapest shipping companies in each case.

Past customer projects indicate that transport costs could be reduced by at least ten percent if a number of these goals are achieved. All of the companies mentioned agree that transport management software which is fully developed from a functional point of view and can be closely linked to the materials requirement process is a key requirement for increasing independence and the degree of control in transport management. The newly integrated transport management solution from SupplyOn – TOMS – fits into this category. For this reason, the companies mentioned above have decided to use TOMS as a way of assuming greater responsibility for procurement logistics. This will enable them to reduce transport costs – contrary to the trend described in the study and predicted by the shipping companies.

TOMS integrates previously isolated follow-up supply processes with shipment and transport optimization, the enlisting of freight services and the issuing/checking of invoices. This makes the entire process – from notifying the supplier of requirements to the receipt of the goods – totally transparent and manageable. The fact that only the goods actually transported are billed and part-loads can be filled up with empties or outbound shipments means that significant savings can be made.

(If you would like to read more about this, you will find more detailed information regarding the solution here: Transport management or on our blog: Success factors in the introduction of a global transport management organization)

What is your procurement logistics strategy for coping with increasing volatility?