“Get the future before it gets you”: full-stack Industry 4.0 solution ONCITE launched

Finally a feasible and scalable digitization solution for industry 4.0

One is almost tempted to twist the eyes and simple go on mute it whenever one hears the terms “Industry 4.0“, “Internet of Things” and “digitization” as repeatedly as they are mentioned in media and technical discussions. Much has been and is being said and written about it. However, we are finally seeing very practical developments in our industry.Those with the greatest external perceptions are certainly those of Volkswagen and BMW: In the spring of this year, both declared that digital production platforms would be set up in cooperation with the hyperscalers Amazon and Microsoft.

Indeed, suppliers are meanwhile confronted with concrete demands not only to develop and deliver assemblies for OEMs, but also – and this is new – to provide all related data, be it in the context of the project up to the SOP (start of production) or also during production. One could also put it this way: Up to now, Tier 1 suppliers have been primarily required to develop products with optimum functionality, quality and costs. Now, they face even higher demands as their ability to provide a “digital twin” throughout the entire product life cycle and to transfer this data in real-time is becoming the elementary prerequisite for doing business with the major automotive manufacturers.

Existing IT is of no help

In times of unfavorable macro-economic conditions – such as trade disputes, Brexit, the increasing technical diversity in drives and vehicles in general, and the gloomy or at least uncertain sales situation – this is not an easy situation for suppliers in the first place. But adding to that, there are new tasks arising for which the existing IT is of no help.

We are starting to see valid and encouraging examples for internal implementations of industry 4.0 scenarios (aka “Smart Factory”), even if these are nowhere implemented and rolled out with standardization in mind. However, when it comes to exchanging data between companies, we are still a long way off to handle scenarios such as those planned by Volkswagen and BMW.

Suppliers are faced with some key issues here: They are aiming to maintain their data sovereignty, but customers ask for much more transparency. Budgets are becoming tighter. But the item eating up the majority of the IT budget, namely the ERP system, is not even capable of meeting the requirements of digitization.

“The cloud on your very own shop floor”: ONCITE enables digital value creation with full data sovereignty

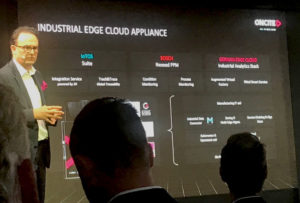

This calls for other solutions to meet these requirements. However, these have not been on the market to date. But this luckily changed last week with the launch of the industrial edge cloud appliance ONCITE by German Edge Cloud, Bosch Connected Industry and IoTOS. This “all-in-one” solution for the manufacturing industry aims to meet exactly these requirements of the future, i.e. digitizing the entire production and its associated processes.

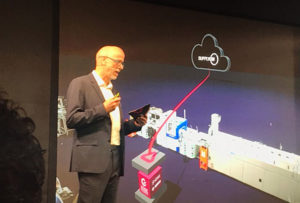

Contrary to most offers, the new solution does not anonymously store data in a cloud, which is always associated with security concerns. Instead, it builds on a cloud edge data center is used, which can be located on a company’s shop floor. It is scalable and thus always tailored to existing or additionally arising requirements. But its major advantage is the high level of security offered: Only the data that ought to be externally transferred will actually be transferred.

The launch was part of a great event at the Rittal Innovation Center of the Friedhelm Loh Group in German Haiger, Hesse. Dr. Loh, as owner of Rittal and many other companies, has always championed the innovative power and talent of German small and medium-sized businesses.

With ONCITE, the subsidiaries German Edge Cloud and IoTOS are now countering the hyperscalers Amazon, Google and Microsoft with a solution specifically tailored to the needs of manufacturing companies: Both in terms of functionality and in terms of the parameters that are always decisive for IT matters, such as information protection, data security and data sovereignty. One could also say that ONCITE combines the best of both worlds, on-premise and on-demand computing.

In this ecosystem, Bosch Connected Industry offers functionalities for monitoring one’s own production. The solution is cutting-edge in terms of both hardware and software components. Among other benefits, it supports in-time scenarios in production plants with 5G.

The best proof there has been something truly excellent created: The renowned Fraunhofer-Gesellschaft not only supported the development of ONCITE, but will also roll out the solution at all their locations, starting with Berlin and Aachen.

Secure customer collaboration via SupplyOn

Once it is clear which data the customers may access, one question remains: How is it securely monitored and transferred to him?

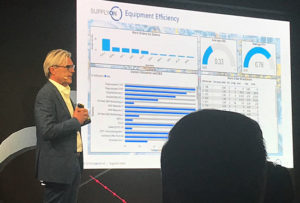

For this, SupplyOn offers the solution. Its ecosystem connects over 100,000 manufacturing companies worldwide, supporting all collaborative processes between suppliers and customers. By using SupplyOn, suppliers can meet the above-mentioned requirements of Volkswagen and BMW after a short project period: The requested data is then transferred in real-time to “Volkswagen Industrial Cloud” or BMW’s “Open Manufacturing Platform”.

Dashboards and cockpits, which are either provided as standard or customized for each process, ensure maximum transparency for purchasing and supplying companies. As mentioned above, data transfer is restricted to the information authorized for sharing.

And here, too, our products are designed for maximum future-proof, thus ensuring investment security: SupplyOn will also to interact with the European cloud solution GAIA-X right from its start.