How to enhance collaboration between procurement and quality management

Digital transformation or not: Working together is often difficult even when system-supported processes are in place. This occurs not just on a large scale, e.g. in the collaboration between companies and their suppliers. It also happens on a small scale, e.g. between different departments. Here companies face challenges such as media discontinuity, a lack of transparency, and processes that are interdependent.

Challenges in procurement and quality management

The manufacturing industry has great potential to tap into the strategically important area of project procurement for newly developed components.

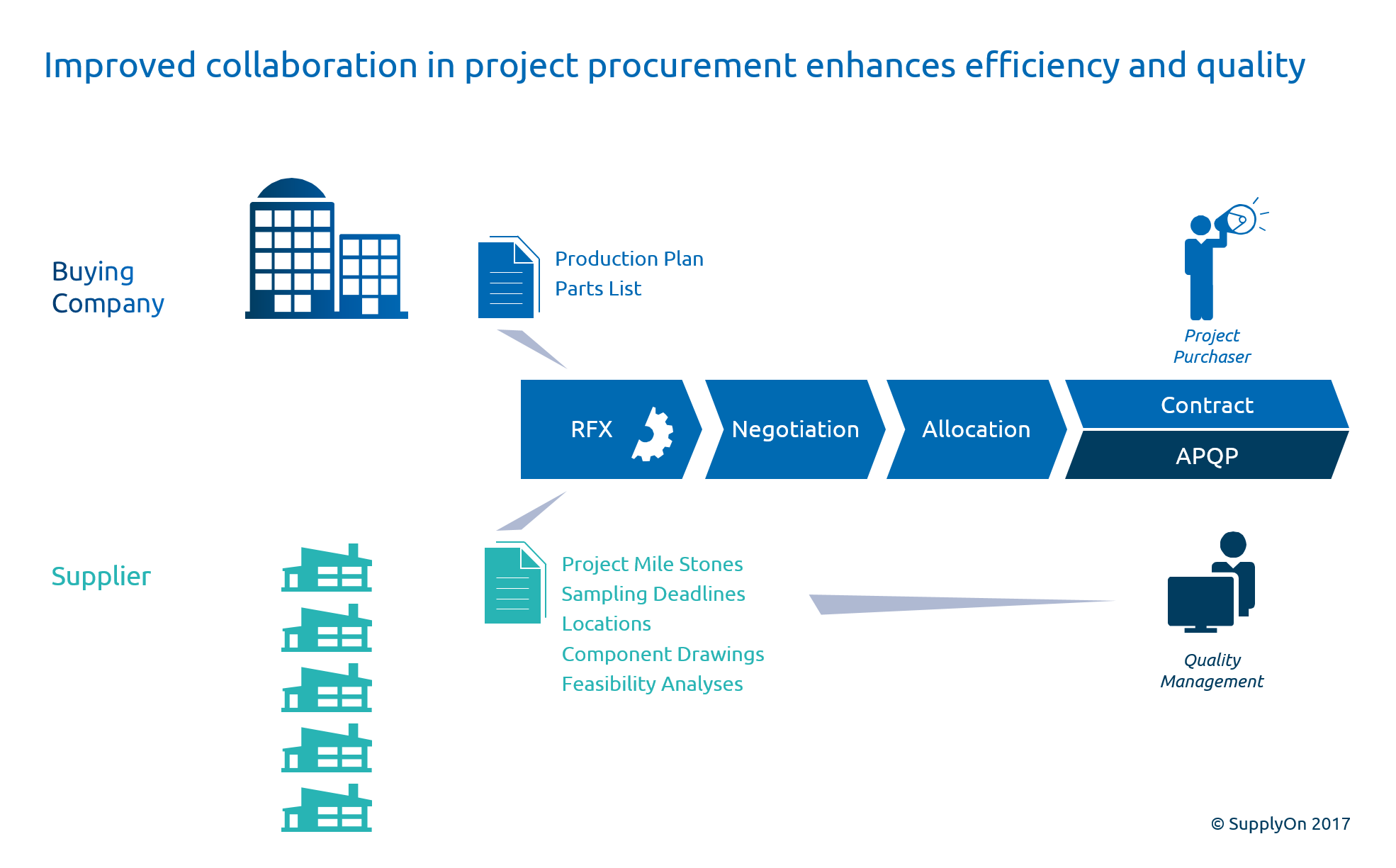

After all, procurement and quality management work together intensively here. For instance, buyers must tell their colleagues in the quality department at the right time that the contract was awarded. If advanced product quality planning (APQP) with a supplier starts too early, the supplier will be informed prematurely of its selection. This can worsen the buyer’s position in potential follow-up negotiations. But if the APQP is started too late, the schedule for project milestones may be endangered.

Frequently, the entire process is also inefficient. Here’s an example: During the bidding phase, buyers ask suppliers for lots of information that is important to quality managers later. At issue are factors such as project milestones, deadlines for samples, involved locations, drawings or feasibility analyses. If buyers and quality managers use different systems, this often means duplicate information. Unnecessary manual extra work is the result.

Achieving better working relationships in project procurement

These problems can only be solved by integrating both processes more closely. After all, these challenges arise because strategic procurement and APQP are generally too far apart.

But just how does this work in daily business operations?

First, the buyer issues a sourcing request. That is, he or she nominates selected suppliers for individual components. For each of these combinations of component and supplier, the system draws up project recommendations and the responsible quality managers are informed. In this way, the quality department is automatically informed and brought into the process at the right time. This eliminates the possibility that the APQP is started too early or late.

But that’s not all: The close link between both processes enables greater transparency later in the project. A complete overview is now possible: How many requests are already in the APQP? And what is their APQP status? These questions can now be answered. As a result, problems can be addressed earlier. And that significantly lowers project risks.

The project benefits at another point, too: Information collected in the procurement process is now available to quality employees. This prevents data from being collected and maintained twice. It also simplifies project management: Frequently, questions about how components were originally specified arise as development progresses. With the new approach, it is much easier for quality employees to see the component drawings.

The ultimate conclusion is this: Close integration of procurement and quality management produces greater transparency and efficiency. The entire process is smoother and more reliable. And the quality of the components improves as well.

(Co-Author: Stefan Wiesi)